Fluid control systems rely heavily on non-return mechanisms to ensure unidirectional flow. ASME standards define the specifications for various components, including these crucial valves. Different chemical compatibilities dictate the selection of materials, impacting durability and operational efficiency. A comprehensive understanding of pressure drop calculations is necessary for optimal system design when integrating specific check valve types and applications. This guide provides an in-depth exploration of check valve types and applications, offering practical insights into their functionalities and integration within diverse engineering contexts.

Image taken from the YouTube channel Production Technology , from the video titled Check Valve Types and Principales .

Crafting "Check Valve Types & Applications: The Ultimate Guide"

A successful "Check Valve Types & Applications: The Ultimate Guide" article requires a structured and informative layout that caters to both novice and experienced readers. The primary keyword, "check valve types and applications," should be naturally integrated throughout, without keyword stuffing, to maintain readability and SEO value. The goal is to offer a comprehensive overview, presented in an accessible manner.

Introduction: Setting the Stage for Check Valves

The introduction should immediately define what a check valve is and its fundamental purpose – preventing backflow. Keep it concise and reader-friendly.

- Briefly explain the concept of backflow and why it’s undesirable in various systems.

- Highlight the role check valves play in preventing backflow.

- State the importance of understanding different check valve types and their specific applications.

- Include a visually engaging image or diagram of a generic check valve.

Understanding the Fundamentals of Check Valves

This section explores the basic operational principles shared by all check valves, regardless of their specific type.

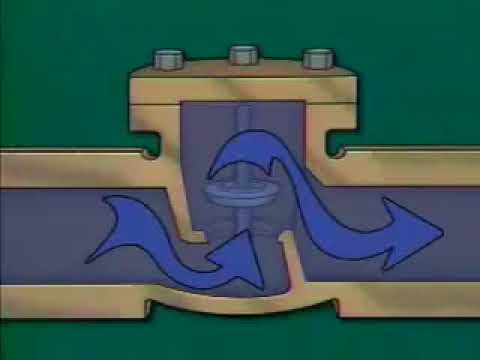

- Explain the mechanism by which check valves operate. Generally, a pressure differential causes the valve to open, allowing flow in one direction, while back pressure forces the valve to close, preventing reverse flow.

- Describe the key components found in most check valves, such as the valve body, disc/ball/flap, and seating surface. A simple diagram could be helpful here.

- Discuss the concept of "cracking pressure" – the minimum upstream pressure required to open the valve.

- Mention factors influencing check valve selection, such as fluid type, pressure requirements, temperature ranges, and application.

Detailed Exploration of Check Valve Types

This is the core of the article, providing an in-depth look at various check valve types, emphasizing their unique characteristics.

Swing Check Valves

- Describe the construction and operation of swing check valves. The disc swings on a hinge or trunnion to open or close.

- Highlight the advantages, such as low pressure drop.

- Note the disadvantages, like potential for water hammer (slamming shut) and limited applicability in pulsating flow systems.

- Provide examples of typical applications, such as wastewater treatment and large diameter pipelines.

- Include a clear diagram showing the swing mechanism.

Lift Check Valves

- Explain how lift check valves function. The disc is lifted vertically off its seat by upstream pressure and returns to the seat via gravity or spring action when flow stops or reverses.

- Differentiate between piston lift check valves and ball lift check valves.

- Mention the advantages, such as suitability for high-pressure applications and tighter shut-off capabilities compared to swing check valves.

- Identify the disadvantages, like higher pressure drop compared to swing check valves.

- Offer examples of applications, such as boiler feed water systems and steam lines.

- Illustrate the lifting mechanism with a cross-sectional view.

Ball Check Valves

- Describe the operation of ball check valves, where a ball rests against a seat to prevent backflow. Upstream pressure pushes the ball away from the seat, allowing forward flow.

- Discuss their suitability for viscous fluids and slurries due to their simple design and self-cleaning action.

- Highlight the potential for ball wear and erosion in certain applications.

- Provide examples of applications in pumps, dispensers, and chemical processing.

Spring-Loaded Check Valves (Poppet Check Valves)

- Explain the function of spring-loaded check valves, which utilize a spring to keep the valve closed until sufficient upstream pressure overcomes the spring force.

- Discuss the advantages of quick response and suitability for preventing water hammer.

- Note their relatively high pressure drop compared to other types.

- Provide examples of applications in hydraulic systems, fuel lines, and compressed air systems.

Duckbill Check Valves

- Describe the unique design of duckbill check valves, featuring a flexible elastomeric sleeve shaped like a duck’s bill. Forward pressure opens the bill, allowing flow, while back pressure closes it.

- Highlight the advantages, such as being clog-resistant and maintenance-free.

- Explain that they’re suitable for wastewater and sewage applications.

- Note their lower pressure ratings compared to other types.

Stop-Check Valves

- Explain that stop-check valves perform the function of both a check valve and a stop valve. They can be manually closed to completely shut off flow, regardless of pressure conditions.

- Describe the scenarios where this functionality is valuable, such as in boiler systems or to allow for maintenance without shutting down an entire system.

Other Specialized Check Valve Types

- Briefly mention other less common but potentially relevant check valve types, such as wafer check valves, dual plate check valves, and nozzle check valves.

- Provide a concise explanation of their specific applications and characteristics.

Applications of Check Valves Across Industries

This section focuses on showcasing the breadth of check valve applications, reinforcing the importance of "check valve types and applications."

- Water and Wastewater Treatment: Preventing backflow in pipelines, protecting pumps, and ensuring proper chemical dosing.

- Oil and Gas: Preventing backflow in pipelines, protecting pumps and compressors, and ensuring safe operation of refineries.

- Chemical Processing: Handling corrosive and hazardous fluids, preventing contamination, and ensuring accurate mixing.

- HVAC Systems: Preventing backflow in heating and cooling circuits, maintaining proper system pressure, and protecting pumps.

- Medical Devices: Controlling fluid flow in IV systems, dialysis machines, and other medical equipment.

- Automotive Industry: Regulating fluid flow in fuel lines, brake systems, and cooling systems.

Factors to Consider When Selecting a Check Valve

This section provides a practical guide for readers tasked with choosing the right check valve for their specific needs.

- Fluid Type: The type of fluid being handled will impact material selection (e.g., compatibility with corrosive fluids).

- Pressure and Temperature: Operating pressure and temperature ranges must be within the valve’s specifications.

- Flow Rate: The valve must be sized appropriately to handle the required flow rate.

- Connection Type: The valve must be compatible with the existing piping system (e.g., threaded, flanged, welded).

- Installation Environment: Considerations should be made for indoor/outdoor use and potential exposure to harsh conditions.

- Maintenance Requirements: Some check valves require more frequent maintenance than others.

- Cracking Pressure: Select based on the system’s minimum operating pressure to ensure proper opening.

Maintaining and Troubleshooting Check Valves

A brief section addressing common issues and maintenance practices.

- Explain potential problems such as valve sticking, leaking, and water hammer.

- Suggest troubleshooting steps for each issue.

- Outline basic maintenance procedures, such as regular inspection and cleaning.

- Emphasize the importance of following manufacturer’s recommendations for maintenance and repair.

FAQs About Check Valve Types & Applications

Got questions about check valves? Here are some frequently asked questions to help clarify the different types and their ideal applications.

What is the primary function of a check valve?

The main job of a check valve is to prevent backflow in a piping system. It allows fluid to flow in one direction only, automatically closing to stop flow if there’s a reversal. This is critical for protecting pumps, preventing contamination, and ensuring process integrity.

What are the key differences between swing check valves and lift check valves?

Swing check valves have a hinged disc that swings open and closed, offering low flow resistance but requiring sufficient flow velocity to fully open. Lift check valves use a disc that lifts vertically, providing tighter shutoff but higher pressure drop. Understanding check valve types and applications is key to proper valve selection.

In what applications are ball check valves commonly used?

Ball check valves, known for their simple design and reliable operation, are frequently used in dirty or viscous fluid applications. You’ll find them in sump pumps, dispensing systems, and other situations where a robust and self-cleaning check valve is needed. The versatility of check valve types allows for wide application.

How does pressure affect the selection of check valve types and applications?

Pressure rating is a critical factor. You must select a check valve with a pressure rating that meets or exceeds the maximum pressure expected in the system. Exceeding a valve’s pressure rating can lead to failure and potential safety hazards, so always consult the valve’s specifications.

So, that’s the lowdown on check valve types and applications! Hopefully, this guide gave you a good understanding. Now get out there and put that knowledge to work!