Minwax, a leading manufacturer, formulates wood stains with a blend of pigments and binders, but the quality of these components significantly impacts shelf life. Knowing the properties of different solvents, particularly the oil-based ones often used by Sherwin-Williams, is crucial in understanding how quickly wood stain deteriorates. The opacity of a stain, often achieved through the careful addition of pigments at local hardware stores, affects how well it can protect wood, but it also influences whether does wood stain go bad over time. Ultimately, proper storage, especially temperature control similar to what’s practiced by professional woodworkers, is a key factor in determining whether does wood stain go bad or retains its effectiveness.

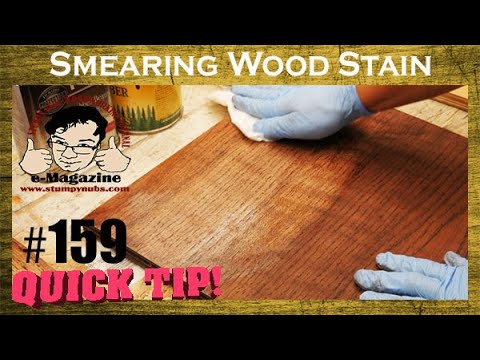

Image taken from the YouTube channel Stumpy Nubs (James Hamilton) , from the video titled FINISHING BLUNDERS: Why wood stain comes off .

Unveiling the Shelf Life Secrets of Wood Stain

We’ve all been there: rummaging through the garage, amidst forgotten tools and half-finished projects, when you stumble upon it—a can of wood stain, its label faded and speckled with dust. A wave of possibility washes over you, quickly followed by a nagging question: is this stuff still any good?

The truth about wood stain and its longevity is less about strict expiration dates and more about understanding its inherent properties and how they are affected by time and storage. Does wood stain go bad? The simple answer is no, not in the way that milk spoils.

However, its usability can degrade significantly over time. This article delves into the factors that influence a wood stain’s shelf life, providing you with the knowledge to determine whether that old can is a treasure or trash.

The Myth of the Expiration Date

Unlike many household products, wood stain rarely comes with a clearly printed expiration date. This is because the components of wood stain – pigments, binders, and solvents – are inherently stable.

However, this stability doesn’t guarantee indefinite usability. The quality and performance of the stain can deteriorate, leading to undesirable results if used unknowingly.

Decoding the Question: Does Wood Stain Really Go Bad?

The more accurate question is: Does wood stain remain usable over time? While the basic components might not decompose in the traditional sense, they can separate, thicken, or otherwise change in ways that compromise the stain’s effectiveness.

These changes are influenced by several factors, including the type of stain (oil-based vs. water-based), storage conditions (temperature, humidity, and sunlight), and whether the container has been properly sealed.

The Key Takeaway: Usability is Key

Therefore, the central thesis is this: While wood stain doesn’t have a strict expiration date, its shelf life is affected by several factors. Understanding these factors empowers you to assess the quality of your stain and determine if it’s still suitable for your woodworking projects.

A little knowledge can save you from wasted time, materials, and the frustration of a poorly stained finish. Keep reading to learn how to identify the signs of spoiled stain and how to maximize its lifespan.

Decoding the Question: Does Wood Stain Really Go Bad?

The more accurate question is: Does wood stain remain usable over time?

While the basic components might not decompose in the traditional sense, they can separate, thicken, or otherwise change in ways that compromise the stain’s effectiveness.

These changes are…

Decoding Wood Stain: Understanding Its Composition

To truly understand how wood stain ages, and thus, whether or not a can of aged wood stain is still useable, it’s essential to break down its fundamental components.

Think of wood stain as a carefully crafted recipe, where each ingredient plays a critical role in achieving the desired color, penetration, and finish.

These core ingredients are pigments, binders, and solvents, each contributing uniquely to the final product.

The Three Pillars of Wood Stain

-

Pigments: These are the finely ground particles that give wood stain its color. Pigments can be natural or synthetic, and the type and concentration of pigment will determine the final hue and opacity of the stain. Higher quality stains typically use finer ground pigments, resulting in a smoother, more even finish.

-

Binders: Binders are the glue that holds the pigments together and allows them to adhere to the wood surface. They form a film that encapsulates the pigment particles and creates a durable finish. Common binders include oils (linseed, tung), resins (alkyd, polyurethane), or acrylic polymers.

-

Solvents: Solvents act as the carrier for the pigments and binders, dissolving the binders and controlling the stain’s consistency. They allow the stain to flow smoothly, penetrate the wood pores, and evaporate, leaving behind the colored film. The type of solvent used is a key differentiator between oil-based and water-based stains.

Oil-Based vs. Water-Based: The Solvent Showdown

The choice of solvent is a primary determinant in the overall characteristics of a wood stain, impacting everything from drying time to cleanup requirements.

Oil-Based Stains and Their Thinners

Oil-based stains rely on petroleum-based solvents like mineral spirits or paint thinner. These solvents offer excellent penetration, a longer open time (allowing for easier blending), and a rich, warm tone.

Mineral spirits is an excellent thinner and is often used for clean-up.

Paint thinner is a stronger solvent and may be more suitable for removing dried stain or cleaning brushes.

Water-Based Stains

Water-based stains, on the other hand, utilize water as their primary solvent. This makes them lower in VOCs (Volatile Organic Compounds), easier to clean up (simply use soap and water), and generally faster drying.

However, water-based stains may not penetrate as deeply as oil-based stains and can sometimes raise the wood grain, requiring more surface preparation.

Understanding VOCs (Volatile Organic Compounds)

VOCs, or Volatile Organic Compounds, are chemicals that evaporate at room temperature and can contribute to air pollution and potential health concerns.

Oil-based stains typically have higher VOC content than water-based stains, making water-based options a more environmentally friendly choice.

However, even low-VOC oil-based stains are available. Always check the product label for VOC content before purchasing.

Understanding the role of each component in wood stain is crucial for predicting its behavior over time. The type of solvent, the quality of the binder, and even the pigment composition can all influence how a stain ages and whether it remains usable after years on the shelf.

The Culprits of Degradation: Factors Affecting Wood Stain’s Shelf Life

Just as environmental conditions affect the aging of fine wine or the fading of vibrant artwork, several factors play a critical role in determining how long your wood stain remains usable. Understanding these culprits of degradation is essential for preserving your stain and ensuring optimal results on your woodworking projects.

At the forefront of these factors are the type of wood stain, the storage conditions in which it’s kept, and the integrity of the container’s seal.

The Type of Wood Stain and Its Longevity

The fundamental composition of different wood stains significantly impacts their shelf life. Oil-based, water-based, gel, latex, and acrylic stains each possess unique characteristics that influence how they age.

Oil-Based Stain

Generally, oil-based stains exhibit greater longevity than their water-based counterparts. The oil base itself is less susceptible to evaporation and the binders tend to be more resilient over time, contributing to a longer usable lifespan.

Water-Based Stain

Water-based stains, while offering benefits like lower VOCs and easier cleanup, may have a comparatively shorter shelf life. The water content can evaporate, leading to thickening or separation of the pigments.

Gel Stain

Gel stain is a unique category. Its thick, gel-like consistency, achieved through the addition of thickening agents, makes it less prone to settling and separation than thinner stains. However, it is still susceptible to drying out if the container is not properly sealed.

Latex and Acrylic Stains

Latex and acrylic stains are water-based formulations that are also susceptible to evaporation and separation. The quality of the acrylic or latex binder will influence the stain’s overall durability and resistance to degradation.

Storage Conditions: The Decisive Factor

Regardless of the type of wood stain, storage conditions are paramount in determining its shelf life. Improper storage can accelerate degradation, rendering even the highest quality stain unusable.

Temperature

Extreme temperatures, both hot and cold, can negatively affect wood stain. High temperatures can cause the solvents to evaporate, leading to thickening and changes in viscosity. Conversely, freezing temperatures can cause water-based stains to separate or become clumpy. The ideal storage temperature is a moderate, consistent room temperature.

Humidity

High humidity can introduce moisture into the container, especially if it is not properly sealed. This moisture can promote the growth of mold or mildew in water-based stains, or cause corrosion in metal containers, contaminating the stain. Storing stain in a dry environment is crucial.

Sunlight

Direct sunlight is detrimental to wood stain. UV radiation can break down the binders and pigments, causing the stain to fade or change color. Always store wood stain in a dark or shaded area away from direct sunlight.

The Importance of Sealed Containers

A properly sealed container is the first line of defense against degradation. Air exposure allows solvents to evaporate, leading to thickening and the formation of a skin on the surface of the stain. It also introduces moisture and contaminants that can compromise the stain’s integrity. Ensure the lid is tightly sealed after each use, and consider transferring the stain to a smaller container if only a small amount remains, minimizing air space.

Red Flags: Recognizing the Signs of Spoiled Wood Stain

Even with the best storage practices, wood stain can sometimes succumb to the ravages of time. Knowing how to identify a compromised can of stain is crucial before applying it to your woodworking projects. Ignoring the warning signs can lead to disastrous results, ruining the finish and costing you time and money.

Thankfully, spoiled wood stain often announces its condition through unmistakable visual cues, changes in consistency, and telltale odors. By learning to recognize these red flags, you can avoid the frustration of working with substandard materials.

Visual Inspection: What to Look For

The first line of defense in determining a stain’s usability is a thorough visual inspection. Before even opening the can, examine its exterior for signs of damage, such as dents or rust. These can compromise the seal and accelerate the degradation process.

Clumping: A Sign of Binder Breakdown

Once opened, the stain should have a smooth, uniform appearance. The presence of clumps, globs, or a cottage cheese-like texture is a clear indication that the binders are breaking down. This can happen due to age, improper storage, or contamination.

If you observe clumping, the stain is likely no longer usable and will not provide a consistent finish.

Separation: Pigment Settling

Another common sign of aging is separation, where the pigments settle at the bottom of the can and the solvent rises to the top. While some settling is normal, excessive separation that cannot be easily remixed indicates a problem.

If, after vigorous stirring, the stain remains separated or has a grainy texture, the pigment may have permanently hardened.

Rust: Contamination from the Can

Metal cans, while durable, are susceptible to rust, especially in humid environments. The presence of rust inside the can can contaminate the stain, altering its color and consistency.

Small amounts of surface rust might be manageable, but significant rust should be a cause for concern, as it can affect the final finish on your wood.

Changes in Viscosity: Thickness and Thinning

The viscosity, or thickness, of a wood stain is critical to its application and performance. Changes in viscosity can significantly impact the final result.

Thickening or Thinning: An Imbalance

A noticeable thickening of the stain can make it difficult to apply evenly, leading to brush strokes and uneven color distribution. Conversely, excessive thinning can result in a weak, watery finish that lacks depth and protection.

In either case, the stain’s ability to properly penetrate and adhere to the wood is compromised.

The Smell Test: Olfactory Warning Signs

Your nose can also be a valuable tool in assessing the quality of wood stain. Unusual odors are often a dead giveaway that something is amiss.

Rancid or Sour Odor: Decomposition

Oil-based stains, in particular, can develop a rancid or sour odor as the oil decomposes. This smell is a strong indication that the stain has gone bad.

Water-based stains may also exhibit an off-putting smell, although it may be more subtle. Any foul or unusual odor should be treated as a warning sign, suggesting that the stain is no longer fit for use.

The separation of pigments, the unsettling clumping, that concerning smell… you’ve assessed the evidence, and the jury is still out on whether your old can of wood stain is usable. But before you commit it to your prized woodworking project, there’s one more crucial step: the ultimate test.

The Ultimate Test: Verifying Stain Quality Before Application

While visual and olfactory clues offer valuable insights into a stain’s condition, the only definitive way to determine its usability is by testing it on a scrap piece of wood. This simple act can save you from potential disasters, like uneven finishes, mismatched colors, or a stain that simply refuses to dry. Think of it as a dress rehearsal before the main performance, a chance to iron out any wrinkles before they become glaring imperfections.

The Scrap Wood Advantage

Why scrap wood? Because it allows you to assess the stain’s behavior without risking your entire project. Select a piece of wood that is similar in species and preparation (sanding, etc.) to the wood you’ll be using for your actual project. This ensures that the test results are representative of how the stain will perform on the final piece.

Testing on scrap wood offers a controlled environment to observe the stain’s absorption, color, and drying properties, without the pressure of potentially ruining your hard work.

Evaluating Color and Consistency

Once you’ve applied the stain to your scrap wood, carefully evaluate the color. Does it match your expectations based on the label or your memory of the stain’s original hue? Sometimes, even if the stain appears normal in the can, the pigments may have subtly shifted over time.

Pay close attention to the consistency of the stain as you apply it. Does it spread evenly, or does it appear too thick or too thin? A stain that is too thick may leave streaks or an uneven finish, while a stain that is too thin may not provide adequate color coverage.

The Drying Time Factor

Drying time is another critical factor to consider. Follow the manufacturer’s instructions regarding drying time, and then patiently observe the stained scrap wood. Does the stain dry within the specified timeframe? Does it remain tacky or sticky long after it should be dry?

A stain that takes an unusually long time to dry, or that never fully dries, is a sign that the binders may have degraded, rendering the stain unusable.

Assessing the Final Finish

Once the stain is completely dry, examine the finish closely. Is the color uniform and consistent across the surface? Are there any noticeable imperfections, such as streaks, blotches, or areas where the stain failed to adhere properly?

If you observe any of these issues, it’s a strong indication that the stain is no longer viable and should not be used on your project.

When to Say Goodbye

Ultimately, the scrap wood test is about risk management. If the stain performs flawlessly on the scrap wood, you can proceed with confidence. However, if you encounter any red flags during the testing process, it’s best to err on the side of caution and dispose of the stain responsibly. While it might be tempting to try and salvage an old can of stain, the potential cost of ruining your project far outweighs the cost of a new can.

That scrap piece of wood has spoken, revealing the true character of your aged stain. Assuming it passed the test, you’re ready to proceed with your project. But what if you want to prevent this whole "will it work?" drama in the first place? The key lies in proactive preservation.

Preservation Strategies: Maximizing Wood Stain’s Shelf Life

Extending the life of your wood stain isn’t about luck; it’s about implementing smart storage strategies. By creating the optimal environment and following a few best practices, you can significantly prolong its usability and safeguard your investment.

The Cool, Dark Sanctuary: Ideal Storage Conditions

Where you store your wood stain is just as important as how you store it. The ideal location is a cool, dry place shielded from direct sunlight.

Think of it like this: sunlight acts as an accelerator, speeding up the degradation process.

Extreme temperatures, whether scorching heat or freezing cold, can also negatively impact the stain’s composition.

A consistently moderate temperature is key to preserving its integrity. Basements, storage closets, or even dedicated shelving in a garage (away from direct sunlight and temperature fluctuations) can work well.

Airtight Defense: The Importance of Sealed Containers

Air is the enemy. Oxygen promotes oxidation, which can alter the stain’s color and consistency.

Ensuring the container is completely airtight is crucial.

After each use, thoroughly clean the rim of the can to remove any dried stain residue that might prevent a tight seal.

A rubber mallet can be helpful to gently and securely close the lid.

For added protection, consider transferring the stain to a smaller, airtight container, minimizing the amount of air inside.

If the original lid is damaged or warped, replace it with a new one designed for paint or stain cans.

The Periodic Inversion: Preventing Separation

Especially for oil-based stains, pigments tend to settle at the bottom of the can over time. This separation can lead to uneven color distribution and inconsistent results.

To combat this, periodically invert the can.

About every three months, turn the can upside down for a few minutes, then return it to its upright position.

This gentle agitation helps redistribute the pigments and maintain a homogenous mixture.

Don’t shake vigorously, as this can introduce air bubbles.

If you haven’t used the stain in a while, stir it thoroughly with a stirring stick before inverting.

By adopting these simple yet effective preservation strategies, you can significantly extend the lifespan of your wood stain. You’ll save money by reducing waste and, more importantly, ensure consistent, high-quality results on your woodworking projects for years to come.

That scrap piece of wood has spoken, revealing the true character of your aged stain. Assuming it passed the test, you’re ready to proceed with your project. But what if you want to prevent this whole "will it work?" drama in the first place? The key lies in proactive preservation.

Responsible Disposal: Safely Saying Goodbye to Old Wood Stain

Knowing when to let go is just as important as knowing how to preserve. Wood stain, unfortunately, doesn’t last forever, and improper disposal can have serious consequences for both the environment and your community.

This section will walk you through the importance of responsible disposal, helping you navigate local regulations and safe methods for bidding farewell to that old can of stain.

Why Proper Disposal Matters

Wood stain, particularly oil-based varieties, is often classified as household hazardous waste. This classification stems from the presence of volatile organic compounds (VOCs) and other potentially harmful chemicals.

These chemicals can contaminate soil and water sources if simply thrown into the regular trash or poured down the drain.

Ignoring proper disposal protocols can lead to environmental damage, posing risks to wildlife, ecosystems, and even human health.

Furthermore, improper disposal can violate local regulations, leading to fines and penalties. It is simply not worth the risk.

Navigating Local Regulations for Hazardous Waste Disposal

The rules surrounding hazardous waste disposal vary significantly depending on your location. It’s crucial to understand and adhere to your local regulations to avoid legal repercussions and ensure responsible waste management.

Your first step should be to contact your local waste management authority.

Many municipalities offer specific guidelines for disposing of household hazardous waste, including designated drop-off locations or scheduled collection events. These services are designed to safely handle materials like wood stain, ensuring they are processed in an environmentally sound manner.

Additionally, some paint retailers or hardware stores may offer recycling or disposal programs for old paint and stain. Check with your local stores to see if they provide such services.

Familiarize yourself with any specific requirements, such as container labeling or quantity limits, to ensure compliance with local regulations.

The Drying-Out Method: A Safe Alternative

In some cases, you can safely dispose of small quantities of oil-based or water-based stain by allowing it to dry out completely. This process renders the stain inert, making it safe for disposal with your regular trash.

How to Dry Out Oil-Based Stain

- Ensure proper ventilation. This is crucial to prevent the buildup of harmful vapors. Work in a well-ventilated area, preferably outdoors.

- Add a hardening agent. Mix in cat litter, sawdust, or a commercial paint hardener to accelerate the drying process. Stir thoroughly until the mixture thickens.

- Allow ample drying time. Let the mixture sit uncovered in a safe location away from children and pets until it is completely dry and solid. This may take several days, depending on the quantity and environmental conditions.

- Dispose of responsibly. Once fully dry, the hardened stain can be disposed of with your regular trash, according to local guidelines.

How to Dry Out Latex/Water-Based Stain

Water-based stains are simpler to dry out. The process is generally the same.

- Ensure proper ventilation.

- Allow the water to evaporate. Leave the can open in a well-ventilated area away from children and pets.

- Speed up the drying (optional). Mix in cat litter, sawdust, or a commercial paint hardener.

- Dispose of responsibly. Once fully dry, the hardened stain can be disposed of with your regular trash, according to local guidelines.

Important Considerations:

- Never pour liquid stain down the drain or into the ground.

- Always check local regulations before using the drying-out method, as some municipalities may prohibit it.

- If you have a large quantity of stain to dispose of, the drying-out method may not be practical, and you should seek professional hazardous waste disposal services.

- Always wear appropriate safety gear, such as gloves and a mask, when handling old stain, especially when using solvents or hardeners.

- Keep drying stain away from open flames and heat sources.

By following these guidelines, you can ensure that your old wood stain is disposed of safely and responsibly, protecting the environment and your community.

FAQs: Wood Stain Expiration and Shelf Life

Here are some common questions about whether wood stain expires and how to maximize its lifespan.

How long does wood stain typically last before it goes bad?

Unopened, oil-based wood stain can often last for several years, even up to 5-10, if stored properly. Opened cans, however, have a shorter lifespan, usually around 2-3 years. Latex or water-based stains may degrade slightly faster. Checking for thickening, separation, or strong odors is key to determine if the wood stain does go bad.

What are the signs that my wood stain has expired?

Common signs that your wood stain has expired or does go bad include a thick, lumpy consistency that doesn’t stir back together smoothly. You may also notice a foul or unusually strong odor. Separation of the pigments and binders is another sign, especially if stirring doesn’t re-integrate them. If it doesn’t perform as expected on a test piece, discard it.

How should I properly store wood stain to extend its shelf life?

Proper storage is crucial to prevent wood stain from going bad. Store wood stain in a cool, dry place away from direct sunlight and extreme temperatures. Ensure the lid is tightly sealed to prevent air exposure. For opened cans, consider transferring the remaining stain to a smaller, airtight container to minimize air contact.

Can I revive dried or thickened wood stain?

Sometimes, you can revive slightly thickened wood stain by adding the appropriate thinner (mineral spirits for oil-based, water for water-based) and thoroughly mixing. However, if the stain is severely dried, separated beyond repair, or smells rancid, it’s best to discard it. Do not use stain that does go bad, because it may affect the final result of the project.

So, there you have it! Hopefully, you’ve got a much better handle on whether **does wood stain go bad**. Happy staining!