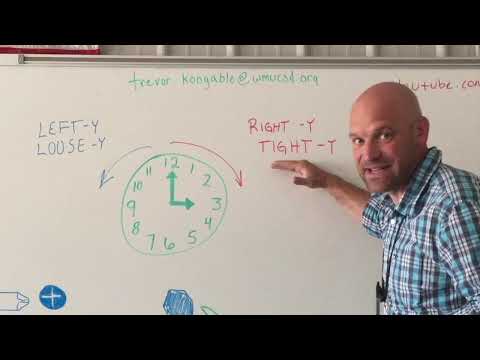

Wrenches, essential tools for any DIY enthusiast, require understanding torque application. Correctly applying torque allows a user to tighten a bolt clockwise, securing materials. The Righty Tighty Lefty Loosey mnemonic serves as a helpful guide, reminding us of the direction for safely tightening. Furthermore, Torque wrenches are used when precise torque is needed. This guide simplifies how to tighten a bolt clockwise, providing practical knowledge applicable to many projects.

Image taken from the YouTube channel Trev Kongable , from the video titled Right -y Tight -y Left -y Loose -y, How bolts and screws turn .

Tighten a Bolt Clockwise: The Ultimate DIY Guide!

This guide provides everything you need to know about tightening bolts clockwise. Proper tightening is crucial for safety and the longevity of whatever you’re assembling or maintaining. This guide will help you understand why clockwise tightening works, how to do it correctly, and potential problems you might encounter.

Understanding the Clockwise Rule

The vast majority of bolts and screws are designed with a right-hand thread. This means that when you turn them clockwise, they move inward (tighten). Understanding this fundamental principle is key to avoiding damage and ensuring a secure connection.

Why Clockwise Tightening is Common

- Standardization: Right-hand threads are the industry standard, simplifying manufacturing and reducing the chance of errors.

- Intuitive Motion: For most people, a clockwise motion feels more natural and provides better leverage.

- Reduced Loosening: In many applications, vibration or rotational forces tend to tighten a right-hand thread further, rather than loosen it.

Exceptions to the Rule

While rare, some bolts use a left-hand thread. These are typically found in specific applications where a clockwise force might otherwise loosen the bolt.

- Identifying Left-Handed Threads: Look for markings on the bolt head, such as "LH" or an arrow pointing counter-clockwise. Always consult the manufacturer’s instructions for confirmation.

Step-by-Step Guide to Tightening a Bolt Clockwise

This section provides a detailed, step-by-step guide to correctly tightening a bolt clockwise.

- Prepare the Bolt and Nut (If Applicable):

- Ensure the bolt and nut (if used) are clean and free of debris.

- Apply a lubricant like anti-seize compound if recommended or necessary (especially for stainless steel). This prevents galling and makes future removal easier.

- Position the Bolt and Nut:

- Insert the bolt through the materials you are joining.

- Place the nut on the threaded end of the bolt.

- Hand-Tighten:

- Turn the nut clockwise by hand until it is snug against the materials. This ensures proper alignment before using tools.

- Choose the Right Tool:

- Select a wrench or socket that fits the nut and bolt head properly. Using the wrong size can damage the fasteners.

- Common tools include:

- Open-end wrench: A wrench with an open "jaw" that fits around the nut or bolt head.

- Box-end wrench: A wrench with a closed "box" that fits entirely around the nut or bolt head.

- Socket wrench: A wrench that uses interchangeable sockets to fit different sizes of nuts and bolts. Sockets are often used with a ratchet handle for efficient tightening.

- Tighten with the Tool:

- Position the wrench or socket on the nut or bolt head.

- Turn the tool clockwise to tighten the bolt. Apply steady, even pressure.

- Achieving the Correct Torque:

- By Feel (Experienced Users): Experienced users can often judge the tightness of a bolt based on feel. This requires practice and understanding of the materials involved.

- Torque Wrench (Recommended): A torque wrench measures the amount of rotational force applied to the bolt. This is the most accurate method for ensuring proper tightening.

- Setting the Torque Wrench: Consult the manufacturer’s specifications for the correct torque value. Set the torque wrench to this value.

- Tightening Until Click: Tighten the bolt until the torque wrench "clicks," indicating that the desired torque has been reached.

Common Problems and Solutions

Even with careful attention, problems can arise when tightening bolts. Here are a few common issues and their solutions.

Stripped Threads

Stripped threads occur when the threads on the bolt or nut are damaged, preventing proper tightening.

- Cause: Over-tightening, using the wrong size tool, or corrosion.

- Solution: Replace the bolt and/or nut. Consider using a thread repair kit if the threads in the receiving material are stripped.

Broken Bolt Head

Excessive force can cause the bolt head to snap off.

- Cause: Over-tightening, using the wrong tool, or a weakened bolt.

- Solution: Extract the broken bolt (this can be difficult; professional help may be needed). Replace the bolt with one of the same size, grade, and thread.

Overtightening

Overtightening can damage the bolt, nut, or the materials being joined.

- Cause: Incorrect torque setting, using excessive force, or failing to heed warning signs (such as the bolt deforming).

- Solution: If you suspect overtightening, loosen the bolt slightly and inspect it and the surrounding materials for damage. Retighten to the correct torque specification. If damage is visible, replace the affected components.

Insufficient Tightening

Insufficient tightening can lead to loosening over time, potentially causing the assembly to fail.

- Cause: Inadequate force, using the wrong tool, or a worn-out fastener.

- Solution: Tighten the bolt further to the correct torque specification. If the bolt still feels loose, inspect it and the nut for damage and replace them if necessary.

FAQs About Tightening Bolts Clockwise

Here are some common questions about tightening bolts clockwise and ensuring you get the job done right.

Why is it usually necessary to tighten a bolt clockwise?

Most bolts are designed with right-hand threads. This means that to tighten a bolt clockwise, you’re essentially engaging the threads and pulling the joined materials together. It’s the standard for a good reason: predictability and ease of use.

What happens if I tighten a bolt counterclockwise when it should be tightened clockwise?

If you try to tighten a bolt counterclockwise when it has right-hand threads, you’ll likely loosen it instead. This can lead to the joint coming apart, or even stripping the threads of the bolt or nut. So, always tighten a bolt clockwise unless it’s a specifically designed left-hand thread.

How do I know if a bolt needs to be tightened clockwise or counterclockwise?

Generally, you can assume a bolt needs to be tightened clockwise. However, if you’re unsure, look for markings or consult the equipment’s manual. Left-hand threads are often marked with an "L" on the bolt head. These require a counterclockwise motion to tighten.

What could happen if I overtighten a bolt when trying to tighten a bolt clockwise?

Overtightening can stretch or damage the bolt, nut, or the materials they’re joining. It can lead to thread stripping, bolt breakage, or even deformation of the connected parts. Always use the correct torque and a torque wrench when precision is needed.

Alright, now you know how to tighten a bolt clockwise like a pro! Get out there, tackle those projects, and remember: righty tighty, lefty loosey!