The aerospace industry relies heavily on rivets, small but mighty fasteners, to join aircraft components. Construction projects also incorporate rivets, demonstrating their structural value in buildings and bridges. Understanding what are rivets used for often starts with recognizing their application in joining sheet metal by Sheet Metal Workers. While welding offers another joining method, the simplicity and reliability of rivets make them a preferred choice for applications where disassembly is not frequently required and a strong, permanent bond is essential. These insights reveal why rivets remain a relevant fastening method.

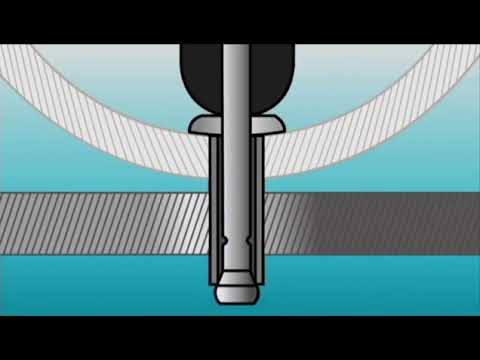

Image taken from the YouTube channel SL Fasteners , from the video titled How Blind Rivet Works? | State enterprises #rivets #blindrivets #fasteners .

Unveiling the Rivet Revolution: More Than Meets the Eye

Consider this: every time an airplane soars overhead, a bridge supports a vehicle, or even when you admire a vintage piece of furniture, rivets are silently playing a crucial role. These unassuming fasteners, often overlooked, are the unsung heroes of countless structures and products that shape our world.

What is a Rivet?

In its simplest form, a rivet is a permanent mechanical fastener. It typically consists of a smooth cylindrical shaft with a head on one end. The installation process involves inserting the rivet through pre-drilled holes in the materials to be joined, and then deforming the tail end of the rivet to create a second head. This process effectively clamps the materials together, creating a strong and permanent bond.

The Ubiquitous Rivet: A World of Surprising Applications

Rivets are not merely relics of a bygone industrial age. They remain a vital component in a surprisingly diverse array of industries. While their presence in aerospace and construction may be well-known, the extent of their application is truly astounding. From the robust construction of ships and automobiles to the intricate designs of electronics and fashion accessories, rivets secure components, ensuring durability and structural integrity.

The ubiquity of rivets is a testament to their reliability, cost-effectiveness, and adaptability. As we delve deeper, the hidden world of rivet applications will reveal some truly unexpected and fascinating uses of this humble yet indispensable fastener.

The Core Functionality of Rivets: A Permanent Bond

Having unveiled the surprising prevalence of rivets, it’s essential to understand precisely how these fasteners achieve their enduring grip and why they are favored in so many diverse applications.

At its heart, the rivet’s functionality relies on a simple yet effective principle: controlled deformation.

The Mechanics of Deformation

A rivet, prior to installation, is essentially a smooth pin with a pre-formed head. Installation involves inserting this pin through aligned holes in the materials to be joined. The tail end of the rivet, protruding beyond the materials, is then deformed, typically by hammering, pressing, or a specialized riveting tool.

This deformation creates a secondary "head" on the tail side, effectively clamping the materials together. The critical element is the expansion of the rivet shank within the hole, creating a tight interference fit. This interference fit, combined with the clamping force exerted by the two heads, generates a robust and permanent joint. The deformed shape locks the rivet in place, preventing it from loosening or backing out over time.

Rivets Versus the Alternatives: Advantages in Specific Scenarios

While welding, screws, and bolts all serve as fastening methods, rivets offer distinct advantages in specific applications.

Strength and Reliability

Riveted joints often exhibit exceptional shear strength, making them ideal for applications where components are subjected to significant transverse forces. Furthermore, well-installed rivets are highly resistant to vibration, a critical factor in industries like aerospace and automotive where constant movement and dynamic loads are the norm. The permanent nature of the rivet connection eliminates the risk of loosening that can occur with threaded fasteners under vibration.

Cost-Effectiveness and Installation

In many high-volume manufacturing processes, rivets offer a cost-effective solution. Automated riveting equipment can install rivets quickly and efficiently, reducing labor costs and increasing production throughput. Moreover, unlike welding, riveting typically requires less skilled labor and avoids the potential hazards associated with high-heat processes.

Material Compatibility

Riveting is particularly well-suited for joining dissimilar materials that may be difficult or impossible to weld effectively. For instance, aluminum alloys, commonly used in aircraft construction, can be readily joined using rivets without compromising the material properties or introducing corrosion concerns. The absence of heat during the riveting process also prevents distortion of the joined materials, a significant advantage in precision applications.

Riveted joints often exhibit exceptional shear strength, making them ideal for applications where components are subjected to significant transverse forces. Furthermore, well-installed rivets are highly resistant to vibration, a critical factor in industries like aerospace and automotive where constant movement and dynamic loads are the norm. The advantages of using rivets become even more apparent when considering the extreme demands of flight.

Rivets Take Flight: Aerospace Applications

The aerospace industry stands as a testament to the rivet’s enduring importance. Within the intricate framework of an aircraft, rivets aren’t just fasteners; they are integral to ensuring structural integrity and, ultimately, safety.

The Backbone of Aircraft Construction

From the earliest biplanes to modern jetliners, rivets have played a pivotal role in assembling aircraft structures. The sheer number of rivets used in a single aircraft is staggering, often exceeding hundreds of thousands. These unassuming fasteners hold together the fuselage, wings, and other critical components, forming a robust and reliable airframe.

The strategic placement of rivets is no accident. Aerospace engineers meticulously design rivet patterns to distribute stress evenly across the structure, preventing localized failures that could compromise the entire aircraft. This painstaking attention to detail underscores the importance of rivets in maintaining the aerodynamic performance and structural stability of aircraft.

Material Mastery: Joining Aluminum and Beyond

Aluminum alloys, prized for their strength and lightweight properties, are the primary materials in aircraft construction. Rivets provide an ideal solution for joining aluminum sheets and extrusions, creating a cohesive structure capable of withstanding the rigors of flight.

The advantage of rivets in this context lies in their ability to create strong joints without compromising the material properties of the aluminum. Unlike welding, which can alter the microstructure of aluminum and weaken it, riveting preserves the integrity of the metal.

Moreover, the strength-to-weight ratio offered by riveted joints is crucial in aerospace applications, where minimizing weight is paramount for fuel efficiency and performance. The inherent vibration resistance of riveted connections further enhances their suitability for the demanding environment of flight. Constant vibrations from engines and turbulent air can loosen other fastening methods.

Reaching for the Stars: NASA’s Reliance on Rivets

The use of rivets isn’t limited to Earth-bound aircraft. Even in the realm of space exploration, NASA relies on rivets for their unwavering reliability in the face of extreme conditions. Spacecraft, satellites, and other spacefaring equipment must endure intense vibrations, extreme temperatures, and the vacuum of space.

Rivets provide a robust and dependable fastening solution in this unforgiving environment. Their resistance to vibration ensures that critical components remain securely attached throughout the launch and operation phases. The ability of rivets to maintain their structural integrity across a wide temperature range makes them an ideal choice for spacecraft exposed to the harsh extremes of space.

From the assembly of the International Space Station to the construction of robotic probes exploring distant planets, rivets continue to play a vital role in NASA’s ambitious missions. Their presence underscores the enduring value of this seemingly simple fastening technology in the face of unprecedented engineering challenges.

Connecting the World: Rivets in Construction and Infrastructure

While rivets are essential in the aerospace industry, their impact extends far beyond the skies. They are equally vital in shaping the world around us through construction and infrastructure. From towering bridges to the steel skeletons of skyscrapers, rivets have played a crucial role in creating the structures that define our cities and connect our communities.

Bridges: Spanning Gaps, Riveted Together

Bridges, especially those constructed during the late 19th and early 20th centuries, are prime examples of the rivet’s dominance. Before the widespread adoption of welding, rivets were the go-to method for joining the massive steel plates and beams that formed the bridge’s superstructure.

The process was laborious, requiring teams of workers to heat the rivets to a malleable temperature, insert them into pre-drilled holes, and then quickly hammer them into shape before they cooled.

Despite the challenges, the resulting joints were incredibly strong and reliable, able to withstand the immense stresses and vibrations generated by constant traffic and environmental factors.

Iconic bridges like the Brooklyn Bridge and the Sydney Harbour Bridge stand as testaments to the durability of riveted construction, with many of their original rivets still in place after decades of service. Modern bridge construction also utilizes rivets, often in conjunction with other fastening methods, particularly in situations where high shear strength and vibration resistance are critical.

Structural Steel Frameworks: Building the Skyline

Beyond bridges, rivets are integral to the structural integrity of buildings, especially those with steel frameworks. In the early days of skyscraper construction, rivets were essential for connecting the steel beams and columns that formed the building’s skeleton.

These frameworks, often hidden behind facades of brick, concrete, or glass, provided the strength and stability needed to support the weight of the building and resist wind loads. The use of rivets in these structures ensured that the connections between steel members remained secure and reliable over time, even under extreme stress.

Rivets contributed significantly to the durability and longevity of countless buildings, including many historical landmarks. While welding and high-strength bolts have become more prevalent in modern construction, rivets still find applications in specific scenarios, particularly when retrofitting or reinforcing existing structures.

The Eiffel Tower: A Riveted Icon

Perhaps no structure embodies the rivet’s contribution to construction more than the Eiffel Tower. Constructed in the late 19th century, the Eiffel Tower is a masterpiece of riveted ironwork. The tower’s intricate lattice structure is held together by approximately 2.5 million rivets, each meticulously placed to ensure the tower’s stability and iconic form.

The Eiffel Tower serves as a powerful symbol of the rivet’s enduring legacy, demonstrating its ability to create structures of unprecedented scale and complexity. It exemplifies the ingenuity and craftsmanship of the era and the crucial role that rivets played in shaping the built environment.

Rivets on the Move: Automotive and Shipbuilding Industries

From the towering heights of skyscrapers to the expansive spans of bridges, rivets have proven their worth in stationary structures. However, their reliability and strength also make them indispensable in industries where movement is paramount: the automotive and shipbuilding sectors. Here, rivets contribute to the durability and safety of vehicles traversing land and sea.

Automotive Applications: Strength in the Chassis

While modern automotive manufacturing increasingly relies on welding and adhesives, rivets still find crucial applications, particularly in areas demanding exceptional strength and resistance to vibration.

Chassis construction, for instance, often incorporates rivets to join frame components, ensuring a robust and stable foundation for the vehicle. Rivets are particularly effective in joining dissimilar materials, such as aluminum and steel, where welding can present challenges.

Beyond the chassis, rivets are used in various other structural components, including:

- Suspension systems: Rivets secure brackets and mounts.

- Body panels: Rivets provide localized reinforcement.

- Interior components: Rivets offer a dependable fastening solution.

Their ability to withstand shear forces and vibrations makes them ideal for applications where failure could compromise safety or performance.

Shipbuilding: A Seaworthy Bond

In the unforgiving environment of the sea, the integrity of a ship’s hull is paramount. For decades, rivets were the primary method for joining the massive steel plates that form the hull, creating a watertight and structurally sound vessel.

The process involved heating rivets to a high temperature and then hammering them into place, forming a permanent bond as they cooled and contracted. This created a seal resistant to the constant pounding of waves and the corrosive effects of saltwater.

Watertight Integrity and Structural Strength

Although welding has largely replaced riveting in modern shipbuilding, rivets remain vital in specific applications, particularly where watertight integrity is critical or where specialized materials are used.

Consider areas around hatches, portholes, and other openings: rivets help maintain a reliable seal and prevent water ingress. In addition, rivets can be used in conjunction with welding to provide added reinforcement in high-stress areas.

Legacy and Modern Applications

The enduring legacy of riveted shipbuilding is evident in the numerous historic vessels that remain afloat today. These ships stand as testaments to the strength and durability of riveted construction. Even in contemporary shipbuilding, rivets offer a reliable solution for specific challenges, ensuring the robustness and longevity of these vital transportation vessels.

Types of Rivets: A Closer Look at Blind and Solid Varieties

From the hulls of ships to the frames of automobiles, rivets work tirelessly to hold our world together. But the term "rivet" is a broad one, encompassing a range of designs each tailored to specific applications and performance requirements. Two of the most prevalent types are blind rivets (often called pop rivets) and solid rivets, distinguished by their installation methods, strength characteristics, and ideal use cases. Understanding the nuances of these two rivet families is critical for any engineer or manufacturer seeking optimal fastening solutions.

Blind Rivets: Accessibility and Ease of Installation

Blind rivets, or pop rivets, derive their name from the fact that they can be installed from only one side of the materials being joined. This "blind" installation capability makes them incredibly versatile, especially in applications where access to the rear of the joint is limited or completely impossible.

The Mechanics of a Pop

A blind rivet consists of two primary components: the rivet body (a hollow, cylindrical shaft with a pre-formed head) and the setting mandrel (a thin rod that runs through the rivet body). Installation is straightforward: the rivet is inserted through aligned holes in the materials being joined. A specialized tool, a rivet gun, then grips the mandrel and pulls it back.

As the mandrel is pulled, it deforms the rivet body, causing it to expand and clamp the materials together. When sufficient force is applied, the mandrel snaps off, leaving the deformed rivet body securely in place. The "pop" sound associated with this breaking mandrel gives the rivet its colloquial name.

Applications of Blind Rivets

The ease and speed of installation make blind rivets a popular choice in a wide range of industries. They are commonly found in:

- Sheet metal fabrication

- HVAC ductwork

- Automotive assembly

- Appliance manufacturing

Because installation doesn’t require specialized skills they are a favorite among DIYers. However, this ease comes with a trade-off.

While convenient, blind rivets generally offer lower shear and tensile strength compared to solid rivets.

Solid Rivets: Strength and Reliability

Solid rivets represent the traditional form of rivet, offering superior strength and durability compared to their blind counterparts. These rivets are characterized by their simple, one-piece construction, consisting of a solid shank with a pre-formed head.

Installation: A Two-Sided Affair

Installing solid rivets requires access to both sides of the materials being joined. The rivet is inserted through aligned holes, and then the protruding shank is deformed – typically by hammering or pressing – to create a second head. This process requires more skill and specialized equipment compared to blind rivet installation.

Strength and Performance

The solid construction of these rivets translates to significantly higher strength, shear resistance, and vibration resistance. This makes them ideal for high-stress applications where structural integrity is paramount. Solid rivets are available in a wide array of materials, from aluminum and steel to copper and titanium, allowing engineers to choose the optimal combination of strength, weight, and corrosion resistance.

Common Use Cases

Their robustness makes solid rivets a critical component in applications such as:

- Aircraft construction (airframes, wing structures)

- Bridge building (structural steel connections)

- Heavy machinery manufacturing

- Historical restoration projects

Because these can handle extreme stress environments, they are more common in the above environments.

Ultimately, the choice between blind and solid rivets depends on the specific application requirements. If ease of installation and accessibility are primary concerns, blind rivets offer a convenient solution. However, when strength, durability, and long-term reliability are paramount, solid rivets remain the superior choice.

From the hulls of ships to the frames of automobiles, rivets work tirelessly to hold our world together. But the term "rivet" is a broad one, encompassing a range of designs each tailored to specific applications and performance requirements. Two of the most prevalent types are blind rivets (often called pop rivets) and solid rivets, distinguished by their installation methods, strength characteristics, and ideal use cases. Understanding the nuances of these two rivet families is critical for any engineer or manufacturer seeking optimal fastening solutions.

Rivets in Action: Metalworking and Manufacturing Processes

Rivets aren’t just fasteners; they are integral to a multitude of metalworking and manufacturing processes. Their effective application relies on understanding not only the type of rivet but also the techniques, equipment, and potential pitfalls involved in creating sound, durable joints.

Riveting Techniques in Metalworking

Rivets play a crucial role in various metalworking applications.

Joining sheet metal is a prime example. In HVAC systems, automotive body panels, and electronic enclosures, rivets offer a clean and reliable method for creating permanent seams.

They are also widely used for securing components. Think of attaching handles to cookware, hinges to doors, or labels to equipment. Rivets provide a robust and tamper-resistant fastening solution.

Proper hole preparation is paramount. The diameter of the hole must match the rivet size closely. Too small, and the rivet won’t fit; too large, and the joint will be weak. Deburring the hole edges is also crucial to prevent stress concentrations.

Automated Riveting in Mass Production

In manufacturing, the speed and efficiency of rivet installation are critical. Automated riveting systems are thus a mainstay in high-volume production environments.

These systems use robotic arms or dedicated machinery to automatically feed, position, and set rivets at a rapid pace.

Automated riveting is commonplace in the automotive, aerospace, and electronics industries, where thousands of rivets might be installed on a single product. The precision and consistency of automated systems ensure uniform joint quality and reduce the risk of human error.

Common Riveting Problems and Solutions

Despite their simplicity, riveting processes can be subject to various issues.

Rivet Cracking: This can occur if the rivet is over-stressed during installation, or if the material being joined is too brittle. Using the correct rivet material and installation force is essential.

Joint Loosening: Vibration or excessive loads can cause rivets to loosen over time. Ensuring proper rivet selection and installation torque can mitigate this issue.

Corrosion: Galvanic corrosion can occur when dissimilar metals are joined with rivets. Using compatible materials or applying protective coatings can prevent this.

Rivet Head Damage: Improper tool selection or installation can lead to damaged rivet heads. Using the right tool and setting the correct pressure is crucial.

Addressing these problems requires a combination of careful planning, proper training, and meticulous execution. By understanding the nuances of riveting techniques and addressing potential issues proactively, manufacturers can harness the full potential of rivets as reliable and cost-effective fasteners.

Rivets Revealed: Frequently Asked Questions

Rivets are more versatile than you might think! Here are some common questions about their uses.

What exactly are rivets and what are rivets used for?

Rivets are permanent mechanical fasteners. They consist of a smooth, cylindrical shaft with a head on one end. They are used for joining two or more materials together permanently.

I thought rivets were just for metal. Can they be used with other materials?

While commonly associated with metal, rivets can be used with various materials including leather, plastic, and even some fabrics. The key is choosing the right rivet material and setting method for the specific application.

What makes rivets so strong compared to screws or bolts?

Rivets create a very strong and permanent joint because the rivet expands to fill the hole and forms a head on both sides of the materials being joined. This distributed clamping force and lack of threads often makes them more resistant to vibration and shear forces compared to screws or bolts.

What are some examples of surprising uses for rivets beyond construction?

Beyond construction, rivets are surprisingly common in things like clothing (especially jeans), aircraft construction, and even some types of furniture. What are rivets used for in these cases? For attaching pockets, crucial structural components, or decorative elements.

So, next time you see a rivet, you’ll know what are rivets used for and that there’s probably more to it than meets the eye, right? Cool stuff, huh! Thanks for hanging out and reading!